About Ecolab’s Bioquell

In hospitals, pharmaceutical manufacturing plants, labs and cleanrooms, reducing the risk of microbial contamination is vital. You need a reliable way to bio-decontaminate your facilities and equipment. Bioquell solutions empower you to improve product and patient safety, meet regulatory and compliance requirements, and reach maximum operational efficiency.

- Effective

Bioquell bio-decontamination equipment uses 35% aqueous hydrogen peroxide to produce hydrogen peroxide vapor, which achieves a 6-log sporicidal kill on exposed, non-porous surfaces. This process kills a wide range of microorganisms including bacteria, viruses, fungi and spores.

- Trusted

Bioquell is used in healthcare and life science facilities around the world to bio-decontaminate operating rooms, patient rooms, pharmaceutical manufacturing centers, and more.

- Regulatory Compliance

Ecolab supports Bioquell technology with professional validation, maintenance and customer service. Bio-decontamination with Bioquell hydrogen peroxide vapor meets or exceeds regulatory standards around the world, including the European Biocidal Product Regulation (BPR).

The Hydrogen Peroxide Vapor

Bio-decontamination Process

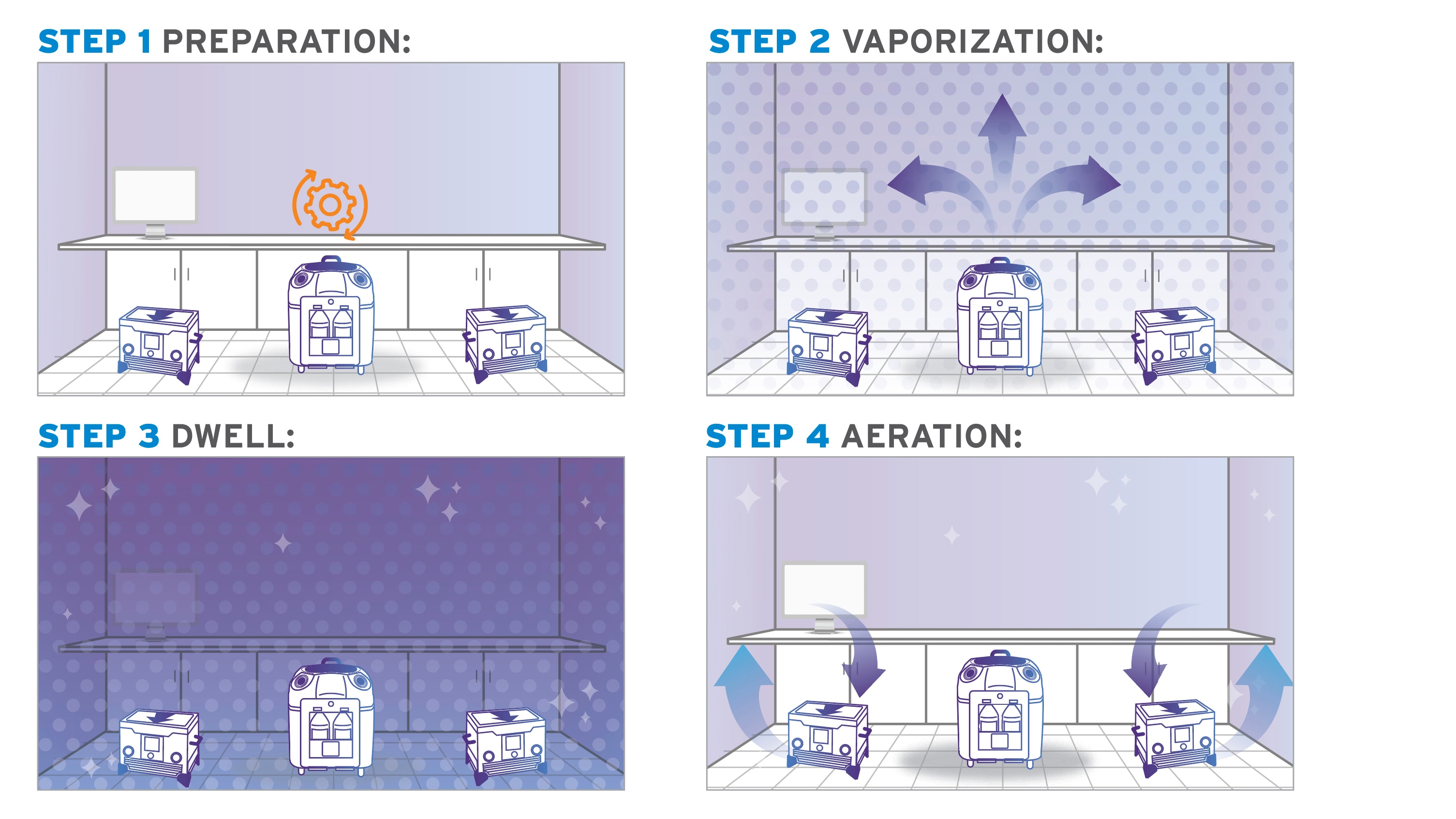

1: Preparation

Prep the room for bio-decontamination: seal vents, and open any cabinets and drawers that require treatment. Seal the door after you exit, then turn on the Bioquell equipment.

2: Vaporization

The system emits the vapor, filling the enclosed area. It deposits a micro-condensation on exposed surfaces, including complex shapes and crevices.

3: Activation Period

Once vaporization is complete, a waiting period allows the hydrogen peroxide time to kill microorganisms on surfaces.

4: Aeration

Lastly, your HVAC system and/or Bioquell aeration units convert the H2O2 into water vapor and oxygen. There are no additional steps to remove residue—the room is ready now ready for use.

Bio-decontamination for Biopharmaceutical Manufacturing

Whether you work in cell and gene therapy or vaccine development, it's important to have a solid bio-decontamination solution in place.

Hydrogen Peroxide Vapor Systems and Services

If you’re seeking a reliable way to kill bio-contaminants in your lab or manufacturing facility, look no further than Bioquell equipment and services.

Validation

To meet regulatory requirements, you may need to provide proof that your bio-decontamination solution works. Ecolab provides validation documentation to support your needs.

Related Bioquell Bio-decontamination

Equipment and Services

Learn more about how Ecolab’s Bio-decontamination Equipment and Services solutions can help your facility produce safe, compliant products that exceed standards, measurably improve operational efficiency and help achieve sustainability goals.