Semiconductor Industry Partners Save Combined USD $720 Million Per Year with Closed-Loop Program

Background

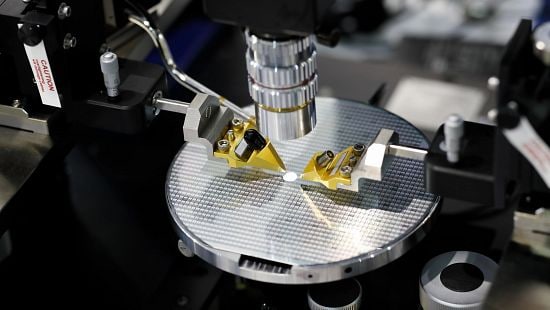

To ensure its microchip circuitry meets design specifications, a US-based semiconductor producer procured 150 microchip testing units as part of a new testing process. Each tester is a complex piece of equipment, featuring a water-cooled circuit constructed with copper piping and an aluminum heat exchanger. The circuit controls the temperature of the synthetic coolant in the test head, wherein the microchip testing takes place.

Soon, the semiconductor producer discovered significant microbiological build-up and corrosion failures in many of the testing units, causing unscheduled outages and interruptions to process every two weeks. After an attempt to design and deploy their own water treatment solution, the testers still experienced recurring catastrophic failures due to microbiological fouling and corrosion.

When a testing unit failed, semiconductor production was negatively impacted while the unit’s cooling system was cleaned and repaired. Each downtime incident cost the semiconductor producer $200,000 per testing unit.

The testing unit failures were costly to the tester manufacturer, too. Each site visit to clean and repair the testing equipment cost the manufacturer $8,400 in labor and travel expenses.

Solution

To resolve the microbiological issues and prevent future corrosion challenges, Nalco Water developed and delivered a comprehensive solution designed to extend and then maintain the MTBF (mean time between failure) of the testers. The solution included:

- A globally deployable water treatment program

- Customized treatment chemistry designed for their system needs

- Complete documentation of system maintenance and chemistry control protocols

- A secure online portal containing SDS for all water-related chemistry

- Analytical support to identify some unknown organic contaminants in order to isolate an operational problem

Results

Both the semiconductor producer and the testing equipment manufacturer saw immediate economic returns with the Nalco Water program. Both parties saw significant cost savings and enhanced productivity while protecting valuable equipment assets.

By reducing downtime due to corrosion and microbiological build-up, the semiconductor producer increased MTBF by 1,200% and achieved annual savings of $720 million. The testing manufacturer also saw savings of $201,600 per year related to the labor and travel costs incurred during on-site service of the testers’ cooling loops.

Annual Savings

PRODUCTIVITY

Cut labor expenses by

$129,600

COSTS

Cost savings from reduced travel

$72,000

ASSETS

Improved MTBF by

1200%

PROFITABILITY

Reduced service and repair costs by

$720,000,000

Total Value Delivered

$720.2

Million Annually